This book covers:

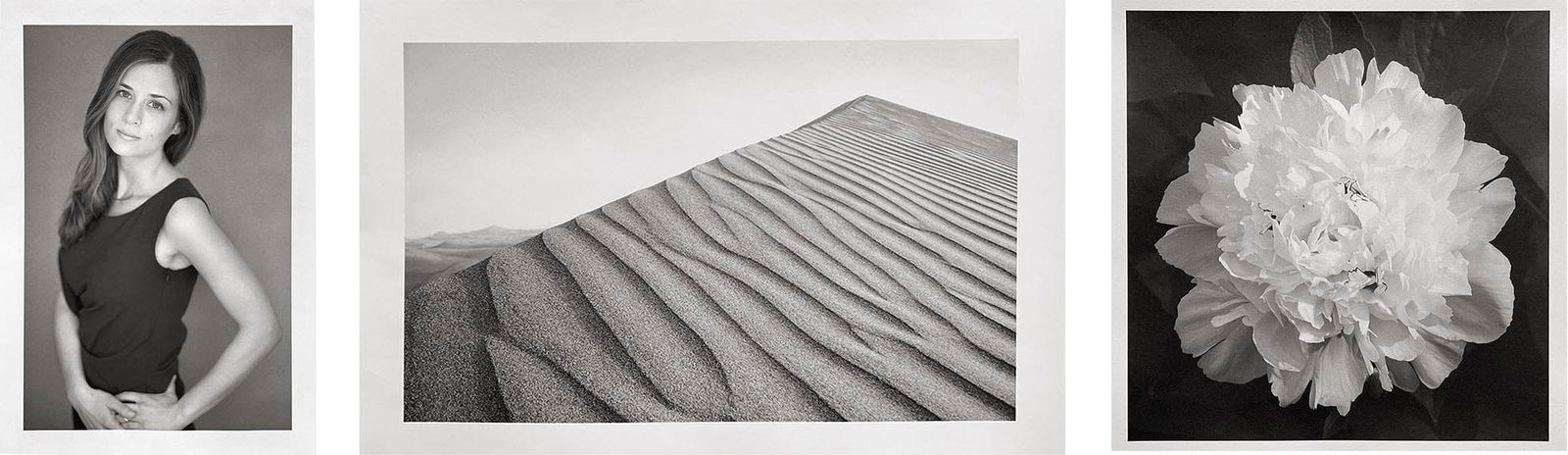

Since this book is only 21 pages long, there is a lot that is not covered. It’s really just a chapter for a book I’m working on for carbon printing, but it will be years until I publish that book. In the meantime, this book is meant to supplement other resources on carbon printing. Below are some samples of carbon transfer prints made with inkjet negatives.

Reviews

There are no reviews yet.